Research Projects

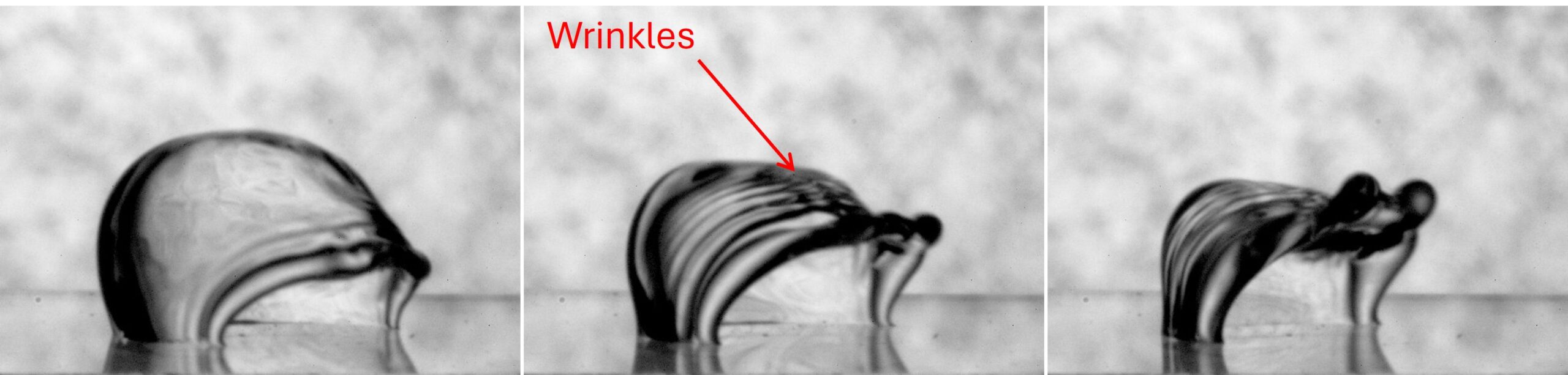

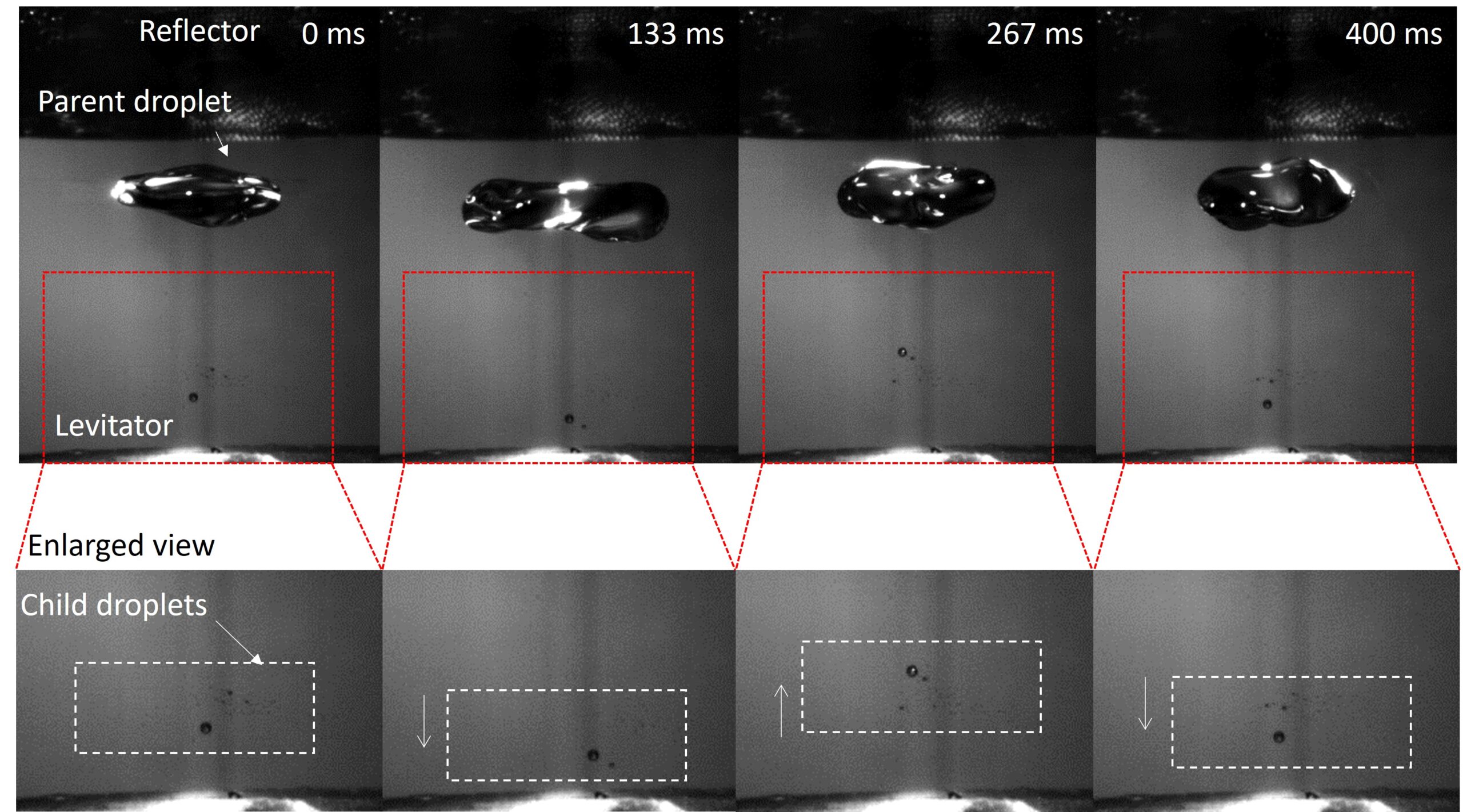

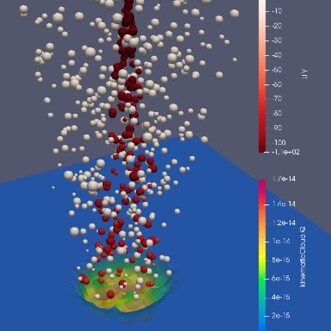

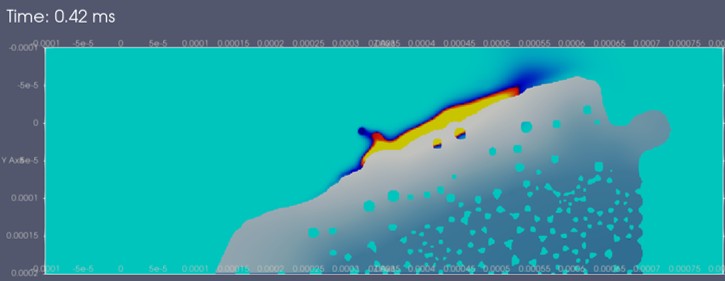

Our laboratory conducts research on spray and combustion control technologies that were originally developed for engines, and we explore their applications in other fields as film formation technology and particle formation method. We also study phase change phenomena between gas and liquid, as well as solid and liquid.

To carry out our experiments, we make extensive use of optical measurement tools such as laser light sources and high-speed video cameras. For numerical simulations, we mainly use the open-source software OpenFOAM to investigate atomization and related spray phenomena.